Bottom

Recycled Rubber Foam

What’s the Special

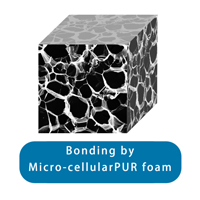

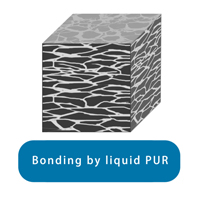

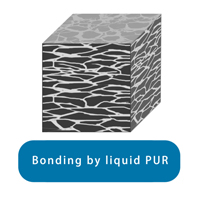

The Recycled Rubber Foam is a green material developed under 3Rs concept (reduce, reuse, recycle) with 50% post-industrial content. It is odorless and does not contain VOCs. Unlike existing recycled foams are bonded with liquid PUR during compression molding, Geltec Recycled Rubber Foam is produced by patented manufacturing process. The scrap rubber foam chips are rebonded by micro-cellular PUR (foam), which brings strong structure while retaining high cushion performance at the same time. The softness is customizable merely by adjusting the material proportion, so the material is structurally sound and uncompressed to retain the good cushioning properties of the material itself. Also, compared to the general compression process, our manufacturing process has higher production efficiency for sooner lead time. Furthermore, the Recycled Rubber Foam is hydrolysis resistant, and it can withstand high temperatures due to thermosetting properties. This material is available for a variety of applications in flooring mats and more.

Characteristics of Recycled Rubber Foam

●

Eco-friendly material based on the 3Rs concept

● Contain 50% post-industrial recycled content

● Strong structure and good strength properties while retaining soft and

cushioning features

● Weather and hydrolysis resistance

● Odorless and VOC free

● Thermosetting material can withstand to high temperature

● Flexible in the adjustment of softness, thickness, and density

Comparison with existing recycled foam on the market

|

Geltec Recycled Rubber Foam |

Existing Recycled Rubber Foam |

Recycled PU Foam | |

| Structure |

|

|

|

| Hardness | adjustable | N/A | N/A |

| Durability | ●●● | ●●● | ● |

| Hydrolysis Resistance | ●●● | ●● | ● |

| Conformity | ●●● | ●●● | ●● |

| Shock Absorption | ●●● | ●● | ●● |

| Impact Noise Insulation | ●●● | ●● | ●● |

| Specific Gravity | 0.3~0.6 | 0.6~0.8 | 0.2~0.4 |

| Patent |

Yes Patented on manufacturing process |

N/A | N/A |

Applications:

Durable Anti-fatigue Mat |

Underlay |