Rubberized Gel Foam

Rubberized Gel Foam

Rubberized

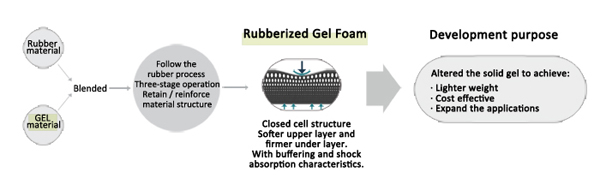

Gel Foam is exclusive material developed for comfortable & cushioning mat

material. Geltec team used the PU Gel material and blended it into the

rubber material. The rubber is used as the carrier to retain PU Gel’s

physical properties of the buffering and shock absorption features and

modified by rubber transforming process to strengthen the tensile strength,

tearing force, slip resistance and oil resistance.

Rubberized

Gel Foam is exclusive material developed for comfortable & cushioning mat

material. Geltec team used the PU Gel material and blended it into the

rubber material. The rubber is used as the carrier to retain PU Gel’s

physical properties of the buffering and shock absorption features and

modified by rubber transforming process to strengthen the tensile strength,

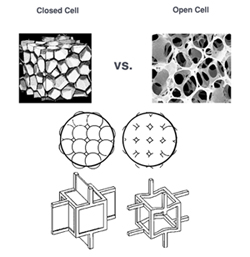

tearing force, slip resistance and oil resistance.Through the process and processing technology, Rubberized Gel Foam is foamed into a “closed cell” structure and one-piece construction. The closed cell foam structure will not absorb the liquids and is easy to clean up. The one-piece construction has a soft upper layer and a dense under layer to provide excellent buffering and supporting effects. The specific gravity (sp.gr) of Rubberized Gel Foam is about 0.2. Compared with the solid PU Gel material, it is lighter weight and its cost is significantly reduced. Rubberized Gel Foam provides users with applications for sports protection, industrial safety, and household life.

Unique process technology and development purpose

Characteristics of Rubberized Gel Foam

● Unique and patented manufacturing process

The material structure and the manufacturing process for Rubberized Gel Foam

is both patented. It is closed Cell Foam structure and one-piece

construction for easy to clean up and maintain. Also the unique one-piece

construction is processed with a soft upper layer and a firmer under layer

in the range of 2 to 3 degrees by Shore C durometer. It provides the mat

with better stability and comfortable characteristics.

● Available choice for various applications

In order to meet the needs of different purposes, Geltec further adjusts the

compressive stress and other physical properties of Rubberized Gel Foam to

create 2 major categories: comfort type and heavy-duty type. It gives the

customer a great ability to cope with the versatile applications of the mat.

| Type: | Comfort | Heavy Duty |

| Suitable applications | Production line/ checkout counter / standing sales / fixing room / required long standing packaging line / protection mat for infant and old people. | Heavy duty working environment/ High pressure resistance environment/ especially design for barrier-free environment. |

● Special processing mode results with a unique

style

During the production process, Geltec has developed a series of special

processing modes for Rubberized Gel Foam. This is to execute the processing

of the mat material, which can result in flexible mat sizes, product shapes,

and even different functional applications.

Material Comparison

| Main Materials | Rubberize Gel foam | PVC/Vinyl-foam | PU-foam | EVA-foam | NBR-foam |

| Wet slip resistance | ●● | ● | ● | ● | ● |

| Dry slip resistance | ●●● | ●● | ●●● | ● | ●●● |

| Conformability | ●●● | ●● | ●●● | ● | ●● |

| Durability | ●● | ●●● | ●● | ●● | ● |

| Stability | ●●● | ●●● | ●●● | ●● | ●● |

| Buffering | ●●● | ●● | ●● | ●● | ●● |

| Comfort | ●●● | ●● | ●●● | ● | ●●● |

| Eco-friendly Material | ●● | ● | ●● | ●● | ● |

| Easy Maintenance | ●●● | ●●● | ● | ●●● | ●● |

| Antibacterial | ●● | -- | -- | -- | -- |

| Fire Resistant | ●● | ● | -- | -- | -- |

| Density ( sp.gr.) | 0.2±0.05 | 0.15±0.05 | 0.25±0.05 | 0.1±0.05 | 0.1±0.05 |

| Price | HM | HM | H | L | LM |

Exercise Mat Series- Functional Mat |

Anti-fatigue Mat Series |

Protect Mat Series |