Comb Gel series (Update!)

Comb Gel series

Comb-Gel Series

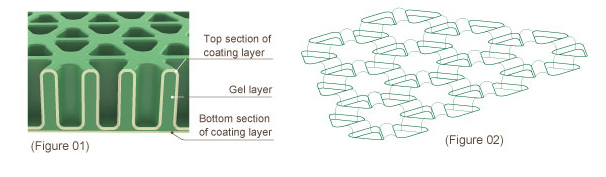

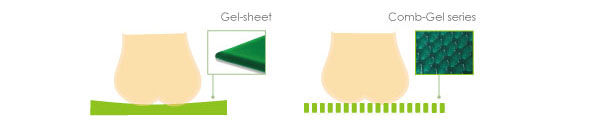

What's Special about Comb-Gel Structure?

Comb-Gel Structure is developed with patent coating film design and

exclusive manufacture technique. As shown as Figure 01, it is made of PU Gel

which is coated entirely with the film layers on surface and bottom into a

Stereoscopic Honeycomb Formation. Employing the honeycomb shaped

configuration (a hexagonal arrangement where the point of contact is

supported by its 6 sides as shown as figure 02) to create a web feedback

mechanism and result in Stress-Strain Benefit.

About "STRESS-STRAIN

ACTION"

About "STRESS-STRAIN

ACTION"

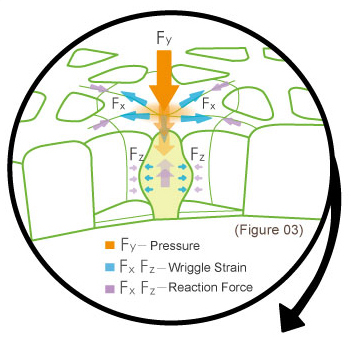

As shown as Figure 03, when pressing

the Comb-Gel Structure toward Fy, the gel with film coating will generate the

wriggle strain toward Fx and Fz to disperse the pressure equally. When the

pressure is released, the reaction force will make the compressed gel revert to

normal. As the result, that interaction makes the Comb-Gel Structure have the

effective pressure dispersion better than the general flat gel sheet.

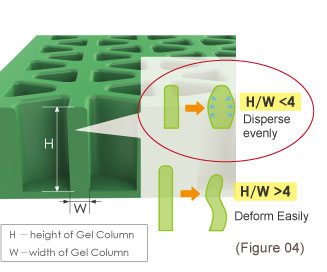

As shown as Figure

04, the formula of H/W<4 is applied by Geltec to set the Comb-Gel

Structure.

As shown as Figure

04, the formula of H/W<4 is applied by Geltec to set the Comb-Gel

Structure.When the gel cube performs the stress-strain action, Fx and Fz can interact equally to not cause deformation. Therefore, Comb-Gel Structure accomplishes the features of soft touch and support.

Features of Comb-Gel Structure

1.Sufficient Pressure Release and Support

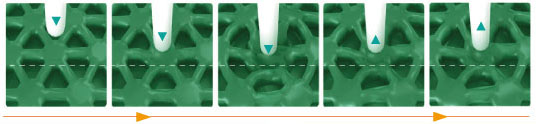

Diagram of the interaction and support of

Comb-Gel Structure

| The wriggle strain is formed to disperse pressure evenly while pressing the Comb-Gel Structure. | The Compression is recovered through the reaction force when the pressure is released. |

2.Reducing Humid and Muggy Feelings

The minimization of contact area between user

and Comb-Gel Structure can avoid the humid and muggy feeling.

3.Excellent Shock Absorption Effect

4.Light weight brings the competitive price

5.Film-Coating Protective Design

The film-coating protective design can prevent the

gel sticky and the bread of bacteria.

6.High temperature sterilization

Comb-Gel is a kind

of crosslinking material which can be treated with high temperature

sterilization and still retain its quality.

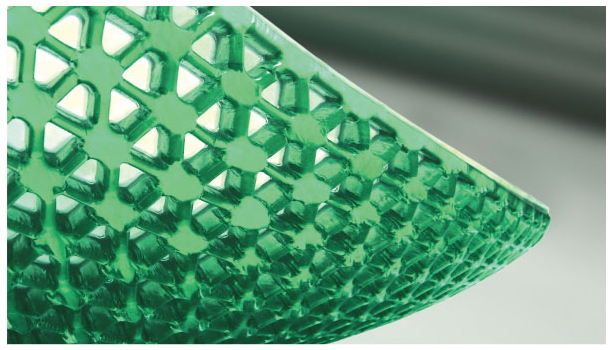

7.ECO Concept

Eco-friendly

material with cooling property helps to save energy and reduce carbon for

environmental purpose.

8.Pleasing transparent appearance

9.Certificate approval

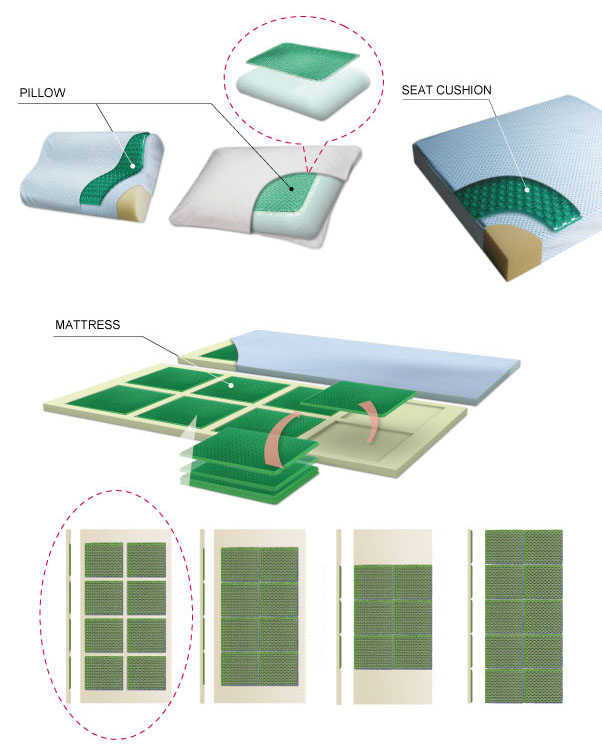

Application of Comb-Gel Series

As the result of the research for the demand of customers, GELTEC makes two

applications for Comb-Gel Series.

Comb Gel Sheet III

Comb Gel 005II Structure

Comb-Gel Sheet III

█Application of Comb-Gel Series

Why

Geltec Develops Comb-Gel Sheet III?

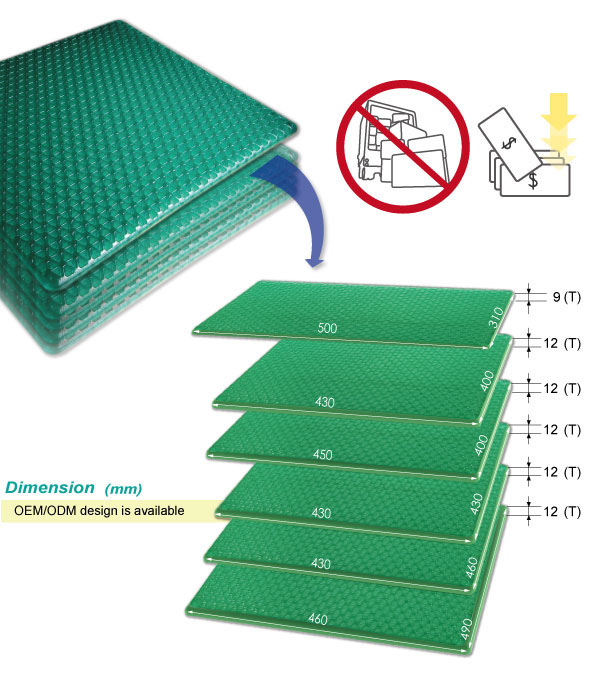

Considering the market demand, Comb-Gel Sheet III is developed to provide

the core value of Comb-Gel and propose for customers. Geltec presents the

concept that supplying Comb-Gel Sheet III with single pieces and conducting

the customers to source foam material such as PU Foam or Memory Foam etc

from their local market unilaterally. In this way, it will efficiently save

the transportation charge by the large volume of foam material and make the

price be more competitive. The single pieces of Comb-Gel Sheet III can be

freely arrayed and overlaid with the foam upon your demand and design for

mattress, pillow, and seat cushion.

YoYou May Use the Single Pieces of Comb-Gel Sheet III

Product

Application of Comb-Gel Sheet III

InIn addition to provide the foregoing material application of the single

pieces of Comb-Gel Sheet III, Geltec has the developments for mattress,

pillow, and seat cushion.

The new generation of Comb Gel Sheet III is thicness of 5mm. It combines

with a latex foam layer to be a mattress protector development.

GSM-004II Mattress

Topper

Covering the Comb-Gel Sheet III with a high-quality cotton cloth, it becomes

a kind of topper protect which can be placed on pillow and seat cushion to

use directly.

GSP Topper

GSC

Toppe

Geltec has the professional manufactring technique to integrate the Comb-Gel

Sheet III with foam. Thus One Piece Type is developed and named “004 Series”

GSM-004

GSC-004

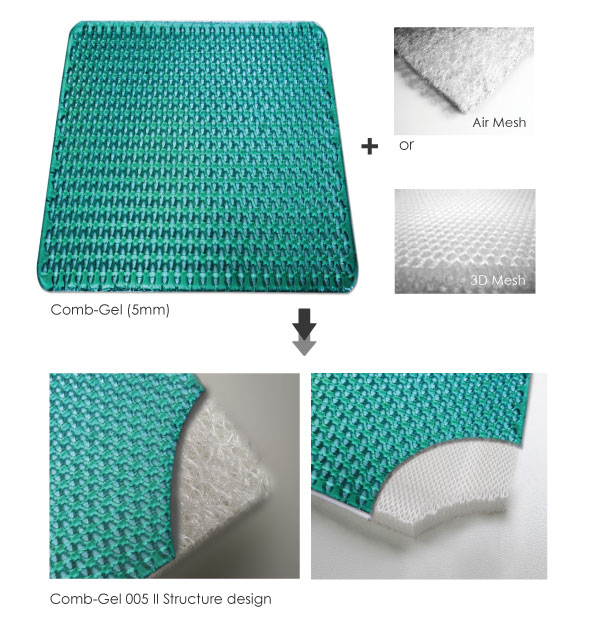

Comb-Gel 005 II Stucture

█Application of Comb-Gel Series

Why

Geltec Develops Comb-Gel 005II Structure?

Comb-Gel 005II Structure is another composition concept of Comb-Gel Series.

It is developed with the consideration to balance the demand among softness,

comfort, ventilation, and cleaning to provide people a cooling and no muggy

feeling especially for the people live in tropic and sub-tropic zones.

Advantages

.Composed by patented combination manufacturing technique.

.In order to solve the uncomfortable touch feeling of Air Mesh/3D Mesh, the

Comb-Gel is chosen to overlay with Air Mesh/ 3D Mesh to provide the soft and

comfortable touch.

.Due to the characteristics of Air Mesh/3D Mesh, Comb-Gel 005II Structure

has the ventilation and heat dispersion effects.

.Lightweight and Portable

.Most cost-efficient

.Easy to Clean

Product Application of Comb-Gel 005II Structure

Comb-Gel 005II Structure is not supplied with a regular specification. It is

operated for an OEM/ODM project upon a customer's demand. Nevertheless, the

available products of Comb-Gel 005II Structure are developed to conduct the

customers to its application,

Comb-Gel 005II Structure is developed to a topper part for mattress, pillow,

and seat cushion.

GSM-005II Topper

GSP-005II Topper

GSC-005II Topper

It is a combination of two substances, Comb-Gel 005II Structure and

Hexagonal Cells, to provide people with a home and nursing products.

GSM-005II + HC Mattress

GSC-005II + HC Seat Cushion

It is a combination of two substances, Comb-Gel 005II Structure and Air

Mesh.

GSC-005II Seat Cushion

Geltec sufficiently uses the fantastic heat dispersion function of Comb-Gel

005II Structure for laptop sleeve to develop an innovative product for

computer accessories.

Cooling Gel Laptop Sleeve